Page 3 - Mt Pleasant Annual Report

P. 3

DOWN THE DRAIN!

Where does it go?

Mount Pleasant Waterworks’ (MPW) wastewater system includes two major components: the collection system and

the treatment plant. Our state-certified licensed operators and sta do an excellent job managing both. Wastewater

collection and treatment is a 24-hour-a-day, 7-day-a-week responsibility. Ultimately, our goal is to protect both the

environment and the quality of life in Mount Pleasant.

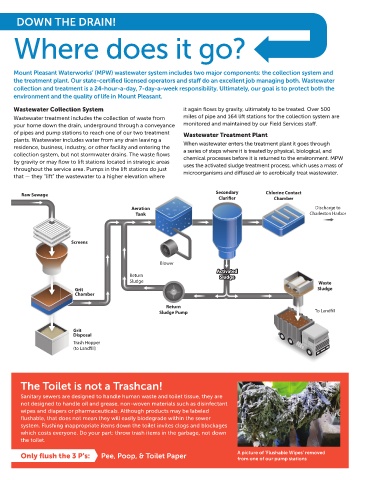

Wastewater Collection System it again flows by gravity, ultimately to be treated. Over 500

Wastewater treatment includes the collection of waste from miles of pipe and 164 lift stations for the collection system are Capital Improvements collects and analyzes over 14,000 samples annually to comply

your home down the drain, underground through a conveyance monitored and maintained by our Field Services sta . Mount Pleasant has seen unprecedented growth over the years with state and federal regulations. We are required to monitor

of pipes and pump stations to reach one of our two treatment Wastewater Treatment Plant and improvements are a continual part of our operations. We are certain parameters daily and report monthly through our

plants. Wastewater includes water from any drain leaving a When wastewater enters the treatment plant it goes through currently undergoing a $75 million dollar upgrade at our Rifle Discharge Monitoring Reports to South Carolina Department of

residence, business, industry, or other facility and entering the a series of steps where it is treated by physical, biological, and Range Road Treatment Plant which will allow us to increase our Health and Environmental Control (SCDHEC). MPW continues

collection system, but not stormwater drains. The waste flows chemical processes before it is returned to the environment. MPW treatment capacity and accommodate growth. to meet and exceed those requirements and we are recognized

by gravity or may flow to lift stations located in strategic areas uses the activated sludge treatment process, which uses a mass of each year for our outstanding track record through the SCDHEC

throughout the service area. Pumps in the lift stations do just microorganisms and di used air to aerobically treat wastewater. Environmental Protection Facility Excellence Award. This is a rigorous award process

that — they “lift” the wastewater to a higher elevation where which demonstrates our hard work and commitment to

MPW operates under an NPDES (National Pollution Discharge excellence. Protecting the environment is our top priority.

Elimination Systems) permit which outlines treatment

Raw Sewage Secondary Chlorine Contact requirements compatible with ambient environmental Below is the 2019 annual summary of MPW’s treated wastewater

Clari er Chamber e uent water quality.

conditions. Our state-certified environmental laboratory

Aeration Discharge to

Tank Charleston Harbor

2019 Wastewater Report Data: Permit # SC0040771

Measure 2019 Actual Regulatory Requirement/Limit

Screens WASTEWATER COLLECTION SYSTEM ANNUAL AVERAGES

Report to SCDHEC

Reportable Sanitary Sewer Overflows (SSOs) 0 total

>5,000 gallons: Limit 2 per 100 miles of pipe

Blower Pipeline Corrective Maintenance 0.45 per 100 miles of pipe No Regulatory Requirement

Activated

A c tiv a t ed

Return Sludge Pipeline Inspection via 20 miles No Regulatory Requirement

Sludge

Robotic Video Camera

Sludge Waste

Grit Sludge Pipeline Cleaned 82 miles No Regulatory Requirement

Chamber

WASTEWATER COLLECTION SYSTEM ANNUAL AVERAGES

Return Flow 5 MGD 6 Million Gallons per Day (MGD) Design Capacity

Sludge Pump To Land ll

Biochemical Oxygen Demand (CBOD) 5 mg/L 25 mg/L Monthly Average

Enterococci 5 MPN/100mL 35 (MPN/100mL) Monthly Geometric Average

Grit

Disposal Ammonia 0.2 mg/L (Mar-Oct) 20 mg/L, (Nov-Feb) Monitor and Report

Trash Hopper

(to Land ll) Total Suspended Solids 5 mg/L 30 mg/L Monthly Average

CBOD % Removal 98% 85% Minimum

TSS % Removal 97% 85% Minimum

CENTER STREET WASTEWATER TREATMENT PLANT ANNUAL AVERAGES

The Toilet is not a Trashcan! Flow 3 MGD 3.7 Million Gallons per Day (MGD) Design Capacity

Sanitary sewers are designed to handle human waste and toilet tissue, they are Biochemical Oxygen Demand (CBOD) 5 mg/L 25 mg/L Monthly Average

not designed to handle oil and grease, non-woven materials such as disinfectant Enterococci 16 MPN/100mL 35 (MPN/100mL) Monthly Geometeric Average

wipes and diapers or pharmaceuticals. Although products may be labeled Ammonia 0.2 mg/L Monitor and Report

flushable, that does not mean they will easily biodegrade within the sewer

system. Flushing inappropriate items down the toilet invites clogs and blockages Total Suspended Solids 8 mg/L 30 mg/L Monthly Average

which costs everyone. Do your part: throw trash items in the garbage, not down CBOD % Removal 97% Monitor and Report

the toilet.

TSS % Removal 96% Monitor and Report

Only flush the 3 P’s: Pee, Poop, & Toilet Paper A picture of ‘Flushable Wipes’ removed COMBINED RIFLE RANGE ROAD AND CENTER STREET WASTEWATER TREATMENT PLANTS

from one of our pump stations

Ultimate Oxygen Demand (UOD) 1,128 lbs/day 11,415 (Mar-Oct) 15,111 (Nov-Feb) Pounds per Day